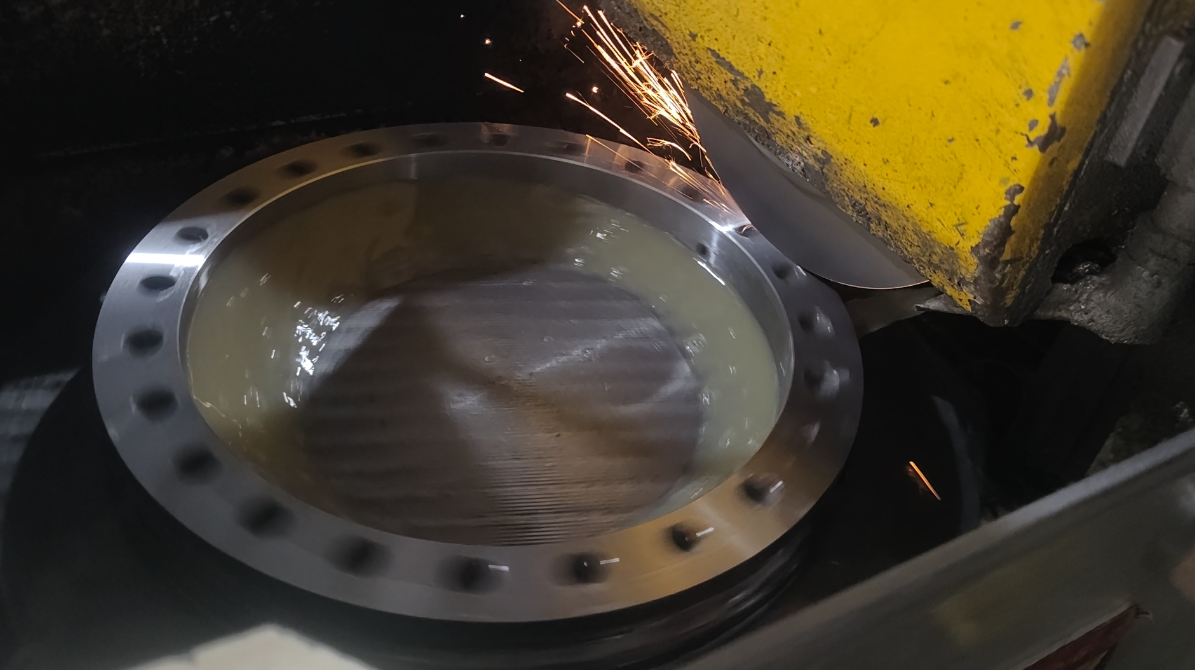

In SWBTEC's slewing bearing production, surfaces designated for galvanizing must undergo grinding (sandblasting) treatment. This is a critical step to ensure galvanizing quality.

Difference between grinding and no grinding:

Ground surface: Thoroughly removes scale, rust, and oil residues, creating a uniform, clean, rough surface. This significantly increases the contact area between the zinc coating and the substrate, resulting in extremely strong adhesion, secure bonding, uniform thickness, and markedly enhanced corrosion resistance and service life.

Un-ground surface: Surface impurities and oxides hinder effective bonding between molten zinc and the steel substrate. This results in poor adhesion, uneven thickness, and susceptibility to peeling and flaking. The final product may exhibit defects such as zinc leakage or zinc nodules, severely compromising corrosion resistance and appearance.

For slewing rings demanding long-term reliability and superior performance, grinding is both essential and the more effective choice. SWBTEC consistently adheres to rigorous surface pretreatment processes, ensuring every galvanized slewing bearing delivers optimal corrosion protection to meet the demands of the most demanding operating conditions.