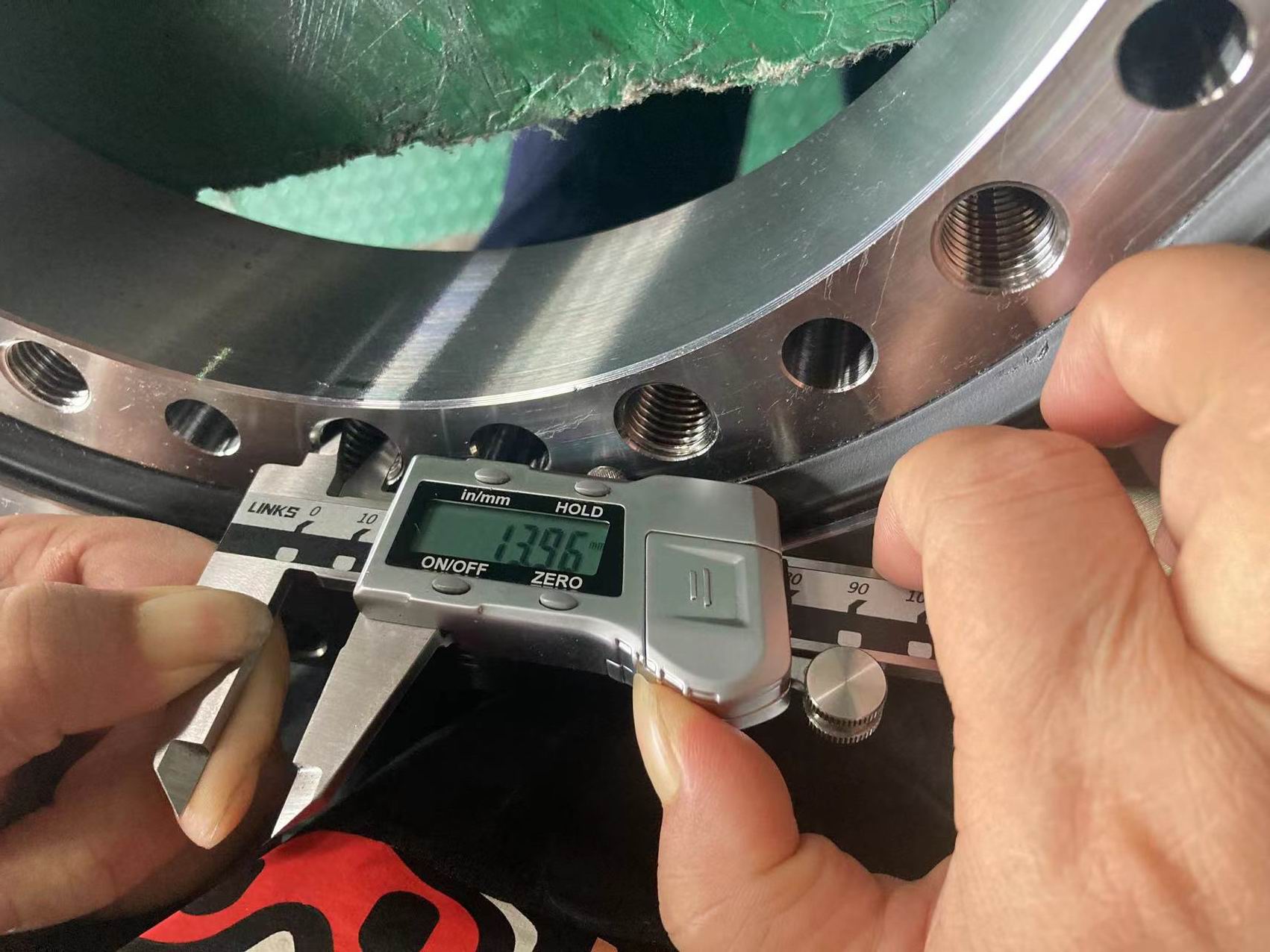

In the field of slewing rings manufacturing, a detail that is often overlooked - the tolerance control of the threaded hole minor diameter is becoming one of the technical watersheds that distinguish high-end from ordinary products.

Minor Diameter tolerance seems to be small, but it affects the whole situation:

Assembly disaster: the small diameter overshoots lead to the bolt false connection or overfilling, which will cause micro-movement wear and tear and will cause the bolt preload failure. In the case of tilting moments (e.g. crane slewing platforms), this failure can directly lead to structural loosening or even fracture.

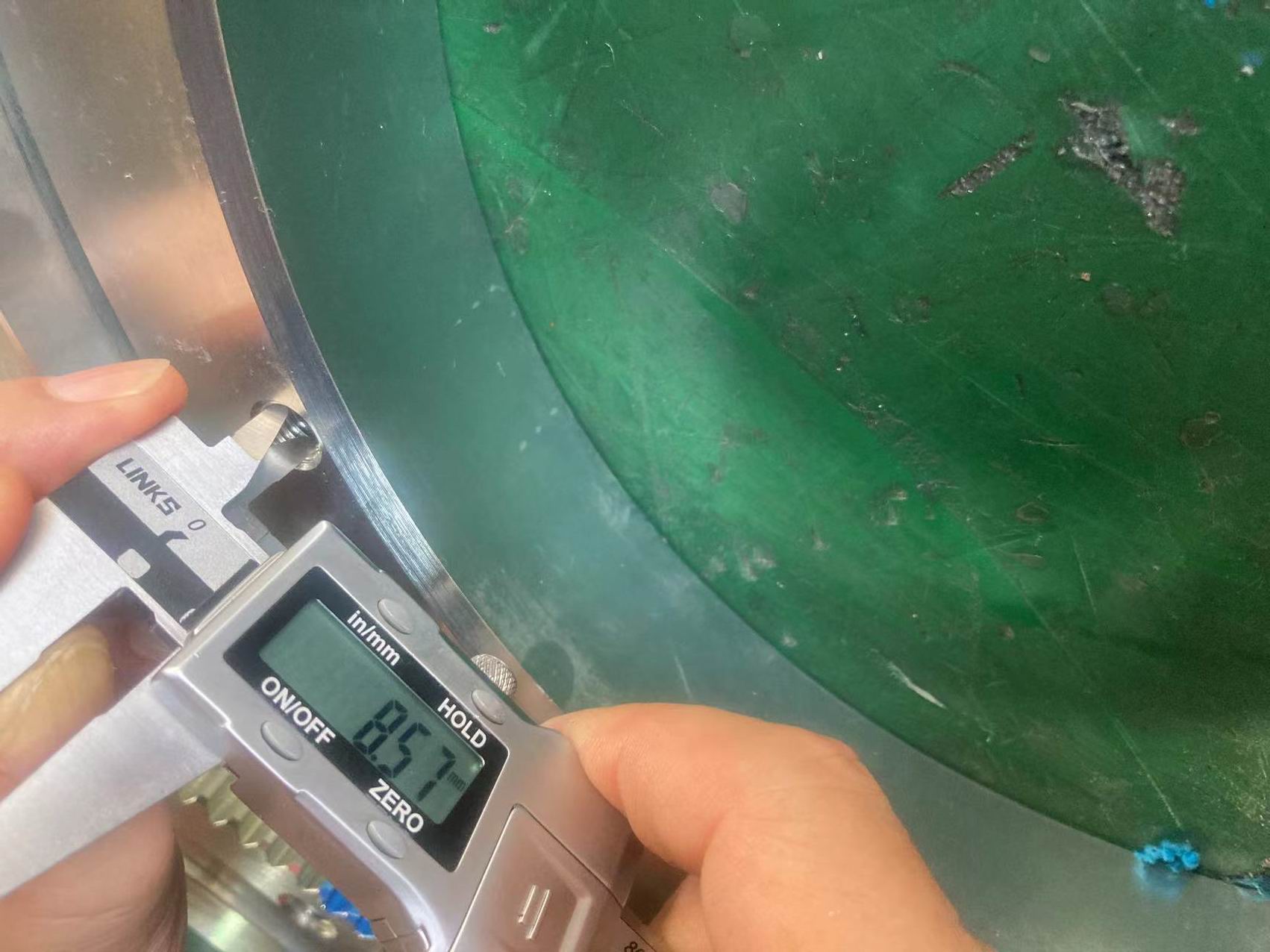

Precision collapse: the gear meshing accuracy of the slewing bearing depends on the positioning of the mounting surface. A deviation of ±0.1mm from the small diameter of the threaded hole can lead to the offset of the mounting surface, resulting in vibration and rattling of the gear transmission, and accelerating the attenuation of the precision of the whole machine.

Corrosion hazards: small diameter processing roughness is too large or shape distortion, will destroy the surface coating denseness. In port machinery, offshore wind power and other salt spray environment, this will induce thread root stress corrosion cracking, life plummeted by more than 30%.

The pain points of China's domestic industry are concentrated and exploded:

Most enterprises are limited by process and testing capabilities, and relax the tolerance of small diameter to 2-3 times of the ISO standard:

Drilling and reaming instead of CNC tapping, resulting in roundness exceeding the poor

Heat treatment deformation is not compensated for, and the thread center diameter is out of round

Lack of a full inspection step, and only sampling and testing of secondary parameters

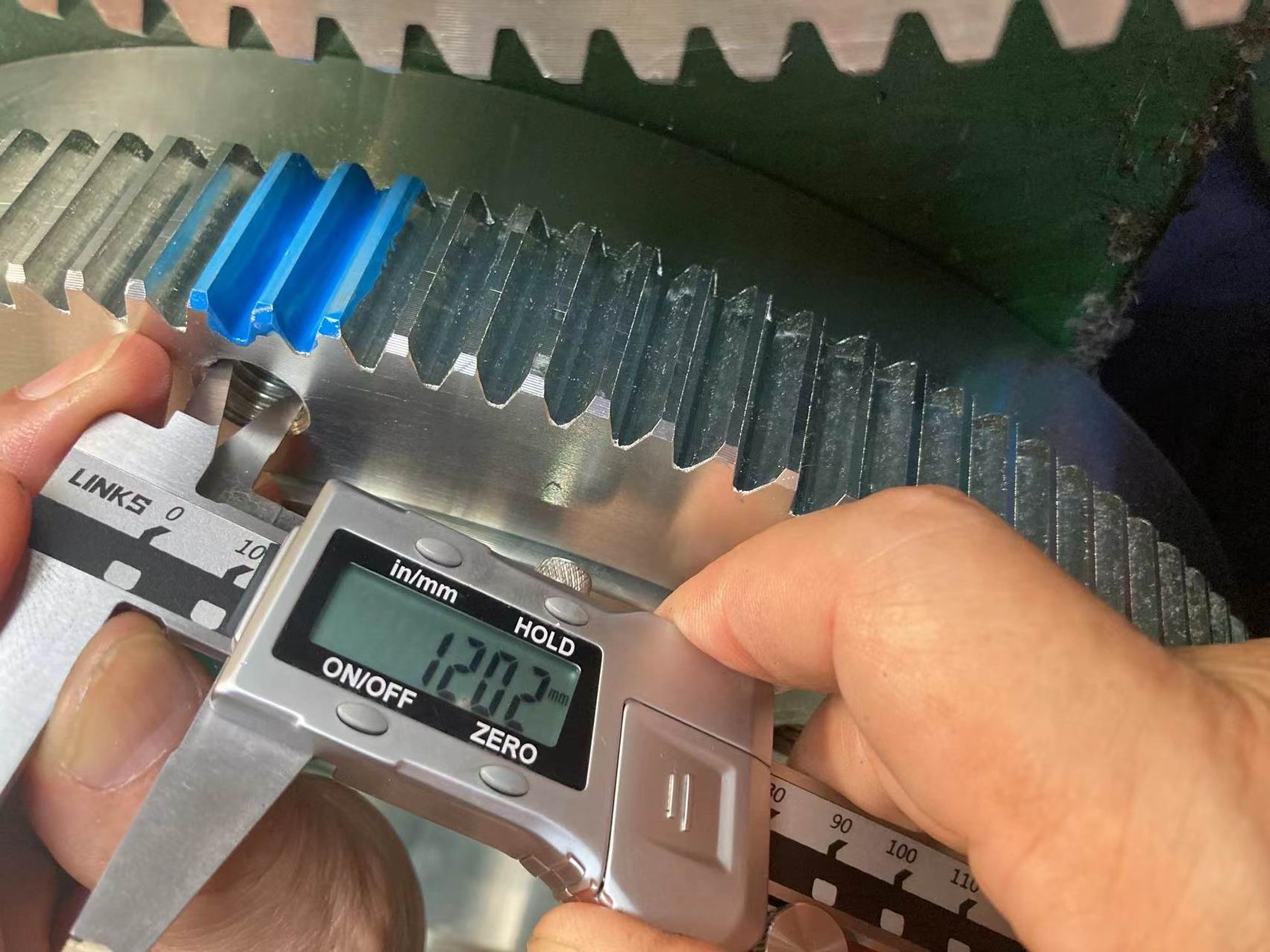

SWBTEC has been using imported German drills and cutting-edge technology to realize precise control of small diameter tolerance, so that every thread can stand the test of ISO and also we can ensure the 6AZ standard.

While most people are still discussing the accuracy of the raceway and steel ball, SWBTEC has already plowed into the microcosm of the thread. Because we know that it is not only the steel ball and the raceway that support the rotation of the gigantic arm of a thousand tons, but also the force transmitted by each thread when it bites.