Slewing bearings must be handled with care during loading and unloading.

It is advisable to transport and store them horizontally, and storage must be in a dry indoor environment.

Lifting should be done with lifting eyebolts in a horizontal manner to avoid collision, especially in the radial direction.

The surface of the slewing ring turntable is coated with an anti-rust agent, and its rust prevention period is generally six months. For storage periods exceeding six months (such as spare parts), it should be re-rust-proof packaged or other storage measures should be taken.

When removing the packaging of the slewing bearing, it must be done carefully to avoid cutting the dust seal. It is best to cut on the outer diameter rather than on the end faces.

The mounting surface of the slewing bearing and the mounting plane of the installation base must be cleaned with an industrial solvent to remove oil stains, burrs, paint, and other foreign objects. Fluorine-containing solvents are strictly prohibited. When cleaning, do not let the solvent flow into the sealing ring and raceway.

The quenching soft zone of the raceway of the slewing bearing (marked with "S" on the outside or at the blocking hole) should be placed in the non-load area.

After the support is hoisted into place, the flatness of the mating surfaces should be checked with a feeler gauge. If there are gaps, re-machining should be performed. If machining is really not possible, filling or local shimming can be used to prevent deformation of the raceway after tightening the bolts, which would affect the performance of the slewing bearing.

Before tightening the bolts, the tooth side clearance must be adjusted according to the highest point of gear radial runout (three teeth marked with green). If there are several small gears, it must be ensured that each small gear is adjusted to the same state to ensure good meshing and alignment with the gear ring. After tightening the bolts, a tooth side clearance check should be performed.

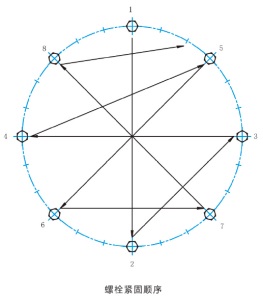

The tightening of the bolts should be carried out continuously in a 180° symmetrical direction, ensuring that the bolts on the entire circumference have the same preloading force. (See the figure below)

Requirements for Bolt Installation

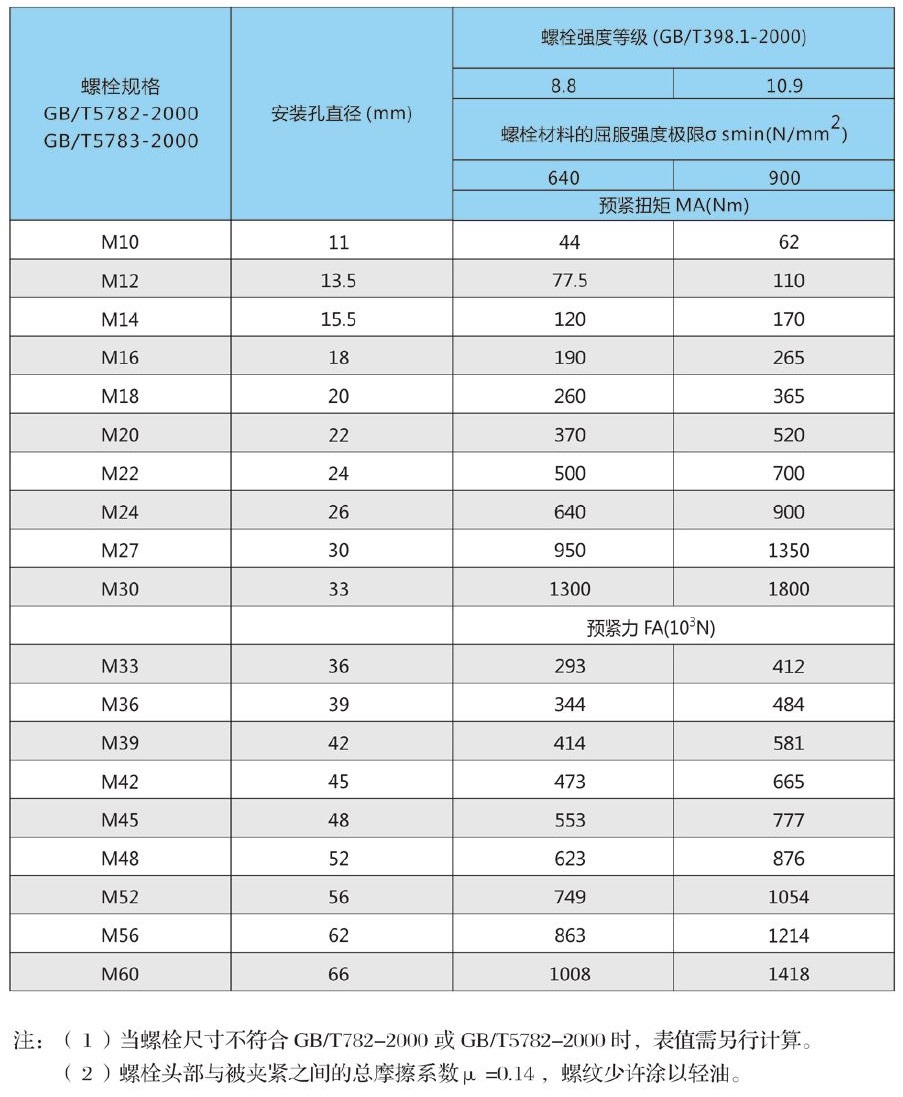

The installation of slewing bearings should select suitable connecting bolts and tightening force. The bolt size should comply with the provisions of GB/T5782-2000 and GB/T5783-2000, and the strength should not be lower than the 8.8 grade specified in GB/T3098.1-2000. It is recommended to use 10.9 grade high-strength bolts. For special purposes, 8.8 grade or 12.9 grade high-strength bolts can be used.

Spring washers should not be used during the installation of slewing bearings. The dimensions of flat washers must comply with GB/T97.1-1985 and GB/T97.2-1985. Quenching treatment should be carried out.

The clamping length of the bolts must be ≥5d (d is the nominal diameter of the bolt).

When tightening the bolts with the base, a certain preloading force must be ensured, generally 0.7 times the yield limit of the bolt.

Preloading Force and Preload Torque

After installation, sufficient grease should be injected into the bearing.

When the slewing bearing leaves the slewing ring manufacturers, a small amount of No. 2 lithium-based grease has been injected into the raceway. Users must inject new grease according to different operating environments.

Slewing bearings should be regularly replenished with grease. Ball slewing bearings should be replenished every 100 hours of operation, while roller slewing bearings should be replenished every 50 hours. In special working environments, such as tropical regions, high dust environments, large temperature variations, and continuous operation, the lubrication intervals should be shortened. Before and after the machine is stopped for long periods of time, new grease must be added, and each time the grease is injected, it must be filled to the point where it seeps from the seal. When injecting grease, the slewing bearing should be rotated evenly to ensure uniform filling.

The tooth surfaces of the slewing bearing must be kept clean. Oil stains on the tooth surfaces should be regularly cleaned and coated with new grease.

After the slewing bearing has operated for 100 hours for the first time, the preloading force of the bolts must be checked. After that, a check should be performed every 500 hours of operation to ensure that the bolts have sufficient preloading force.

During the use of the slewing bearing, the rotation condition of the bearing should be observed at all times. If abnormal noises, impacts, or sudden increases in power are discovered, the machine should be stopped immediately for inspection and troubleshooting. If necessary, disassembly and inspection should be performed.

It is prohibited to flush the bearing with water during use to prevent water from entering the raceway of the bearing. It is also strictly forbidden for hard objects to approach the gear engagement area.

The integrity of the bearing seal should be checked frequently. If the sealing strip is found to be damaged, it should be replaced in a timely manner to prevent foreign objects from falling into the raceway.