The hardened grinding roughness of slewing bearing raceways is usually required to be controlled between Ra 0.4μm and 0.8μm to ensure good contact fatigue performance and wear resistance. Proper roughness reduces stress concentration and the risk of microcracks, while optimizing lubrication and reducing frictional wear.

If the roughness is too high (e.g. Ra>1.6μm), it will lead to uneven distribution of contact stress between the raceway and rolling body, accelerate fatigue spalling and shorten the service life; while the roughness is too low (e.g. Ra<0.2μm), although it can reduce friction, it may be difficult to form a lubrication film due to the surface being too smooth, but increase the risk of adhesive wear.

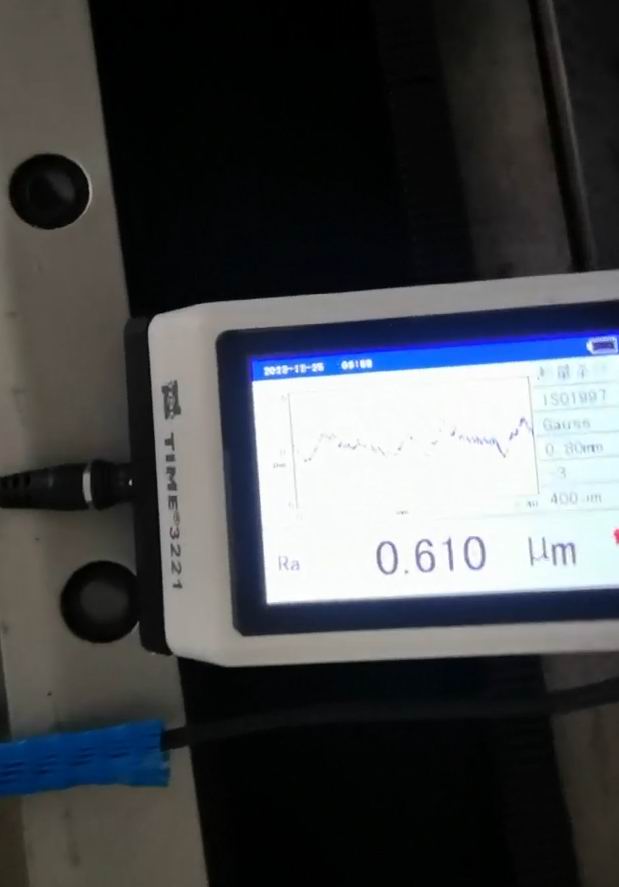

Therefore, strict control of grinding roughness is one of the key factors to improve the service life of slewing rings, SWBTEC has been strictly adhering to the roughness of the raceway after quenching is not more than 0.8μm, which is one of the magic weapons that we have never received any complaints about the quality of the raceway.