In the world of rotating machinery, be it cranes, excavators, wind turbines, or even telescope mounts, there exists a crucial but often overlooked component known as the slewing bearing. Slewing bearings play a pivotal role in facilitating smooth rotation while bearing heavy loads and moments. This blog delves into the inner workings and significance of slewing bearings, shedding light on this unsung hero of mechanical engineering.

A slewing bearing, also known as a slewing ring or turntable bearing, is a specialized type of rolling-element bearing designed to support axial, radial, and moment loads while enabling rotational movement. Unlike traditional bearings that primarily handle radial loads, slewing bearings are engineered to withstand immense loads and allow for rotation around a fixed axis.

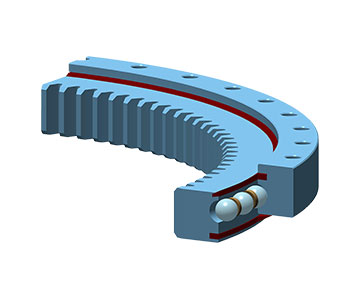

Slewing bearings have a unique construction, consisting of four major components:

1. Raceways: These are the main circular tracks on which the rotating and stationary elements of the bearing interface. The raceways are hardened and precision-machined to reduce friction and wear during rotation.

2. Rolling Elements: Slewing bearings utilize rolling elements such as balls, cylindrical rollers, or tapered rollers to enable smoother rotation between the raceways. The choice of rolling elements depends on the specific application and load-carrying capacity required.

3. Cage: The rolling elements are held in place by a cage, which maintains the correct spacing and distribution of the rolling elements. The cage ensures uniform load distribution and prevents friction between rolling elements.

4. Seals and Lubrication: To protect the internal components from contaminants and ensure proper lubrication, slewing bearings are equipped with seals. These seals help to retain the lubricant inside and prevent the entry of dust, dirt, or water.

Slewing bearings are available in various configurations to suit different applications and load requirements:

1. Single Row Ball Slewing Bearing: Ideal for light to moderate loads and rotational movement, these bearings consist of a single row of balls between the inner and outer raceways.

2. Double-Row Ball Slewing Bearings: These bearings feature two rows of balls, providing enhanced load-carrying capacity and improved stability during rotation.

3. Cross Roller Slewing Bearings: Utilizing crossed cylindrical rollers, these bearings are highly efficient in supporting radial and axial loads while offering precise rotation.

4. Three-Row Roller Slewing Bearings: Designed for heavy-duty applications, these bearings boast three rows of rollers, enabling them to handle substantial axial and radial loads with ease.

Slewing bearings, like crane slew ring, are integral components in various industries and applications, including:

1. Construction Machinery: In excavators, cranes, and concrete pumps, slewing bearings support the rotational movement of the equipment, allowing for efficient material handling and positioning.

2. Renewable Energy: Wind turbines rely on large slewing bearings to enable the yaw and pitch movements of the turbine blades, optimizing energy generation.

3. Industrial Machinery: Slewing bearings are used in heavy-duty turntables, welding positioners, and robotics, where precise rotation and load-bearing capabilities are essential.

4. Astronomy and Telescopes: In telescopes and astronomical observatories, slewing bearings facilitate smooth movement for accurate tracking of celestial objects.

To ensure the longevity and optimal performance of slewing bearings, regular maintenance is critical. This includes proper lubrication to reduce friction and wear, inspection of seals for any damage, and periodic checks for signs of misalignment or fatigue.

Slewing bearings might not be as well-known as other mechanical components, but their impact on various industries is undeniable. These robust bearings enable the smooth rotation of heavy machinery, significantly contributing to the efficiency and functionality of countless applications. Whether it's a massive construction crane or a cutting-edge telescope, slewing bearings provide the stability and support that keeps our world rotating smoothly.