Why do slewing rings forging steels made from identical materials vary so greatly in price and quality?

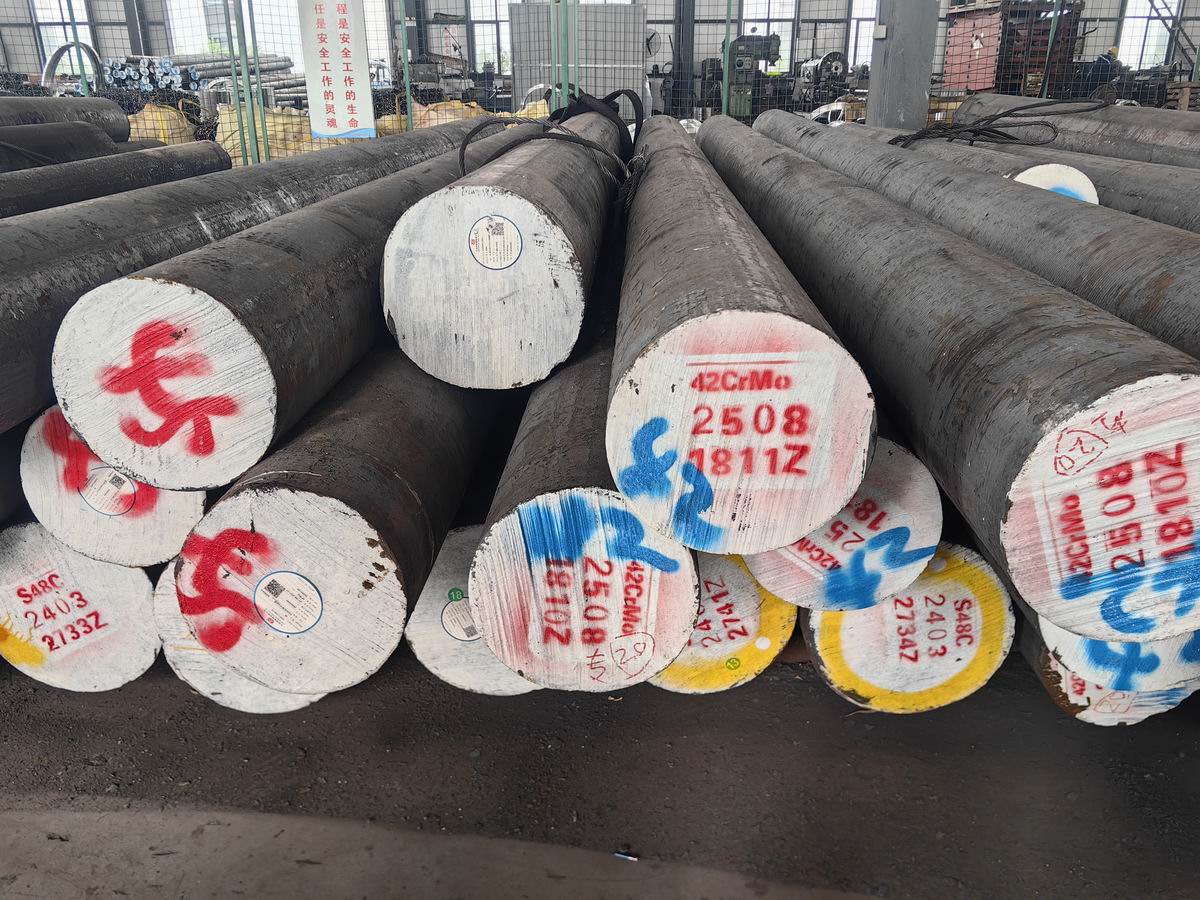

As a slewing rings professional manufacturer in China, we confront a daily reality: why do slewing bearing forging steels of the same 50Mn or 42CrMo material command such disparate prices from different suppliers? More crucially, why do their quality performances differ so dramatically?

Based on our extensive experience, two primary factors underlie this phenomenon.

I. The Root Cause Lies at the Source: Ingot Origin Determines Foundational Quality

We insist that forging steel suppliers must utilise ingots produced by major domestic steel mills (such as Masteel, etc.). This is because large steel mills possess comprehensive quality control systems, with rigorous inspections at every stage from raw materials to finished products.

However, many suppliers in the market opt to source ingots from smaller steel mills to reduce costs. The production processes and quality control of these smaller mills are often unreliable, leading directly to inherent defects in the blanks – such as high levels of internal inclusions and inconsistent composition. This ultimately results in serious issues during use, including cracks.

Cheap ingots will ultimately cost you dearly.

2. Cutting corners in the process: Cost reduction must not come at the expense of quality

Even with qualified ingots, the production process for forging steel remains critical. Forging temperature control, heat treatment techniques, cooling rates... every step influences the final product's performance.

Regrettably, some manufacturers cut corners here: shortening heat treatment times, lowering forging temperatures, simplifying process steps—all to reduce production costs, yet at the expense of product reliability and lifespan.

Our Approach: Dual-Layer Rigorous Control

Recognising the critical importance of raw materials, we implement dual safeguards:

Source Control: We not only require suppliers to provide ingot origin certificates but also conduct regular on-site audits of forging steel manufacturers to ensure their production processes meet our standards.

Comprehensive Inspection: Upon arrival of each batch of forging steel, we conduct stringent testing, including:

Chemical composition analysis

Hardness testing

Mechanical property testing (tensile strength, impact test, elongation, reduction of area)

Quality is our passport to export markets

The fact that the majority of our products are exported to Europe and America is no coincidence. It is precisely this near-obsessive rigour in raw material selection that has earned our slewing bearings an international reputation, while safeguarding our customers from downtime losses and safety risks caused by component failure.

Selecting a slewing bearing is not merely choosing a component; it is choosing reliability and peace of mind. We implement rigorous quality control from the very outset, ensuring every layer is meticulously vetted.

Because we understand: quality is never a compromise.